Whether you’re looking to install a new pallet racking system or reconfigure your existing storage, taking the time to thoroughly plan a new warehouse layout can streamline your warehouse operations and maximise storage capacity.

Follow our step-by-step guide to planning the ideal warehouse layout for your space, products, and processes.

Step 1: Measure Your Warehouse

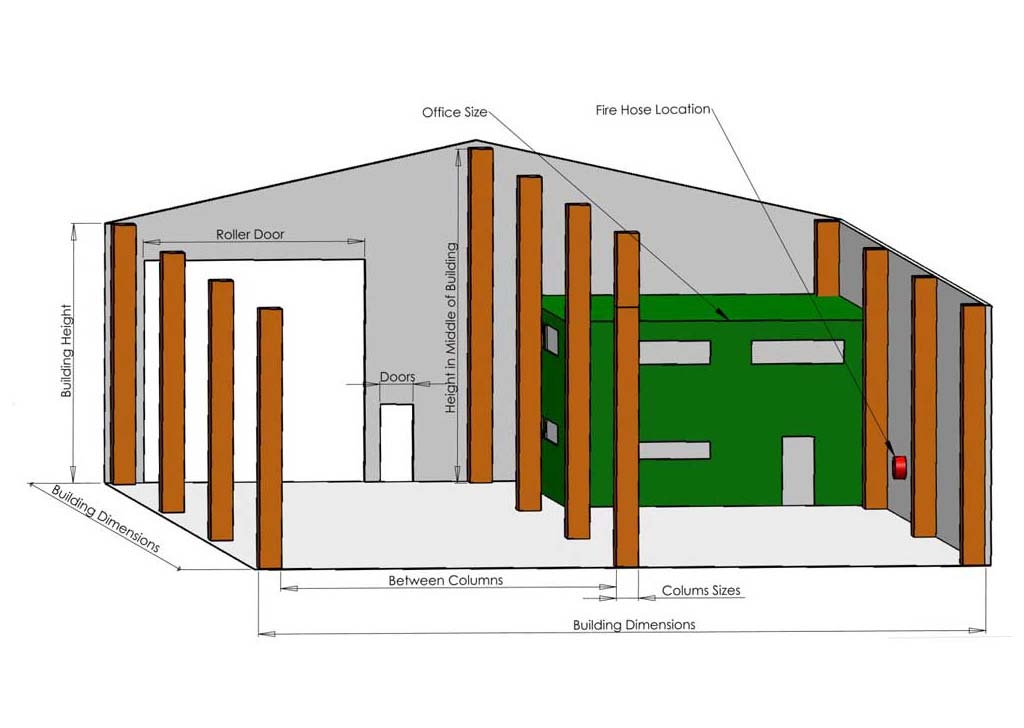

The first step when planning your warehouse layout is measuring the available space. To begin with, measure from wall to wall and include any columns, pipes, corners, stairs, offices, toilets, and anything else that could get in the way of your pallet racking.

As you measure, create a rough sketch of your measurements including any obstructions to create a basic warehouse layout.

You will also need to measure the height of the building to ensure that you make full use of all of the space you have available, as well as to avoid ordering racks that are too tall to fit in your warehouse. If, like most warehouses, your warehouse has a pitched roof, ensure to measure from both the peak of the ceiling, as well as measuring the ceiling height at the sides of the building.

Top Tip:

When measuring your warehouse, don’t measure from point to point (eg. wall to left side of door, left side of door to right side of door, right side of door to wall) as this will create a running measurement. This means that if one of your measurements is wrong it will throw out the rest of your measurements.

Instead, measure back to the same point (eg. wall to left side of door, wall to right side of door, wall to wall).

Step 2: Identify Potential Hazards

Before you can start planning where your racking system will go you will need to identify potential hazards that could be caused when installing pallet racking, such as limiting access to a fire exit or blocking air vents.

As well as identifying potential safety hazards, you should also take note of key areas where pallet racking could negatively affect your warehouse operations. For example, partially obstructing a high traffic route with a pallet rack could reduce productivity and reduce the efficiency of your warehouse operations.

Similarly, blocking essential power outlets with a pallet racking system could also hinder your warehouse processes and should be taken into account when planning a layout.

As you identify potential hazards or obstacles, mark them on your sketched warehouse layout to avoid obstructing them with racking.

Step 3: Measure Your Pallets

Another essential step in planning your warehouse layout is taking into account the size of your products or pallets to be stored. You will need to measure the height, width, depth and weight of your standard pallets or products. This is a crucial step as your product measurements will affect the type of racking system you need as well as the layout of the racks.

Additionally, taking careful measurements of your products before planning your layout and ordering your racking will ensure that your pallet racking system can actually be used to store your products.

Step 4: Consider Your Manual Handling Equipment

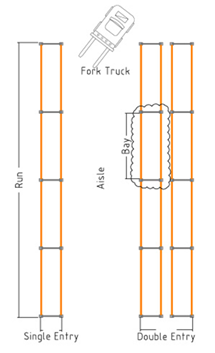

Another factor to take into consideration when planning your warehouse layout is your manual handling equipment. For example, the turning circle of your forklift should be used when determining the aisle width. This will ensure that your manual handling equipment is able to be easily operated within your warehouse and reduce the risk of damage to your racking system due to forklift collisions.

This is an essential step as minimising aisle width can greatly increase warehouse storage capacity. However, if your forklifts cannot be easily operated within the aisles of your racking system your warehouse processes will be slowed and the risk of racking damage will be greatly increased.

Top Tip:

A standard ride on forklift has a turning circle of about 4.5 metres.

Step 5: Order Racking To Suit Your Needs

Once you have measured both your warehouse and your products and taken into account the space required for your manual handling equipment, you will have all of the information you need to order the perfect pallet racking system.

There is a wide range of pallet racking systems and other storage options available, so to ensure that you order the ideal storage solution for you needs contact a pallet racking specialist. MACRACK has a team of experienced pallet racking specialists to assist you in choosing the right pallet racking system that will maximise your warehouse storage capacity and optimise your warehouse operations.

Step 6: Installation & Beyond

To ensure that your new pallet racking system will stand the test of time it is important to have the racks professionally installed to meet all Australian Standards for steel storage racking.

Additionally, you may want to consider installing racking protection to prevent racking damage and reduce the risk of a racking collapse. It is also important to conduct regular pallet racking inspections. Not only are regular pallet racking inspections a requirement under the Australian Standards AS4084:2012, conducting regular inspections will help to prevent damage to your products and pallet racking system, as well as ensuring the safety of your workers.

Free Warehouse Design Layout

If you don’t have the time to carefully measure your warehouse and products to create a perfectly designed warehouse layout, let us do it for you! Take advantage of MACRACK’s free warehouse design layout offer. We can even meet you on site to take measurements of your warehouse, free of charge, and create an accurate design layout that will allow you to visualise where your equipment will be located and where the racking would be most effective.

Call us today on 1800 048 821 to discuss how we can design, build, and install the perfect pallet racking system for your warehouse.