Free Design Service

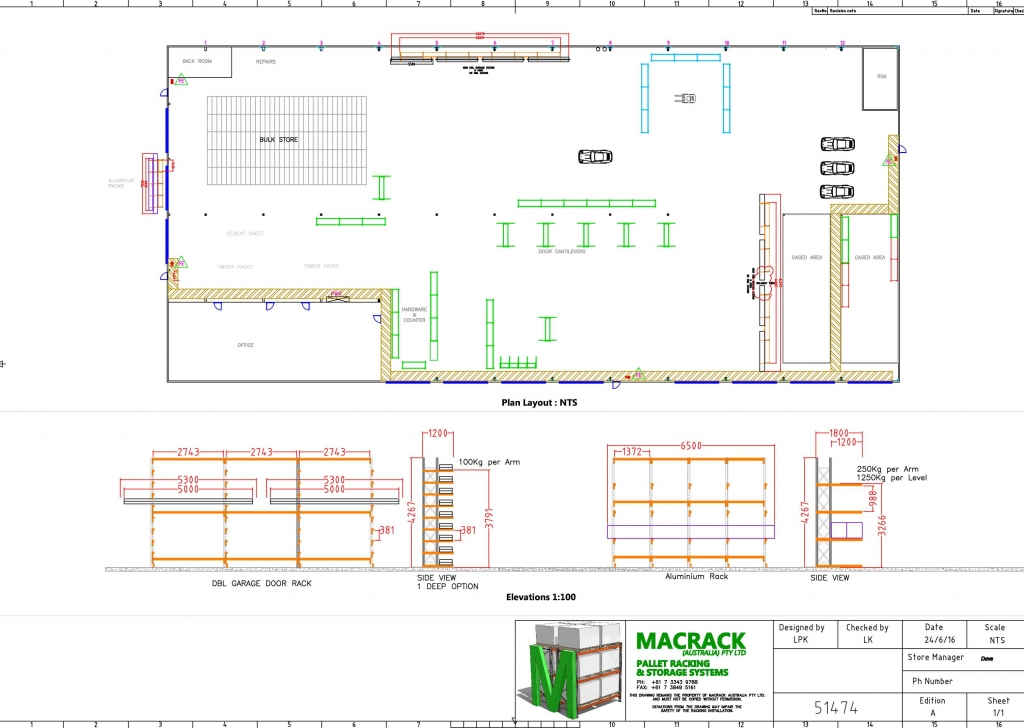

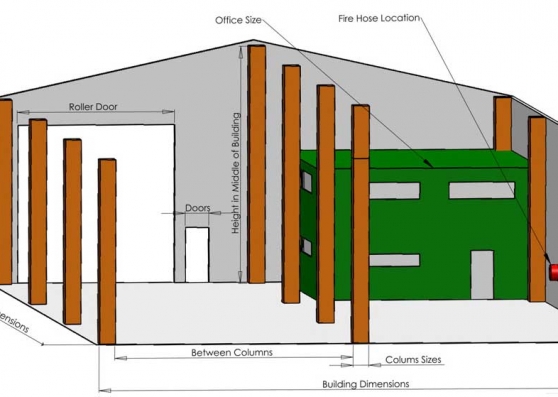

Macrack offers a free warehouse design service. This includes a MACRACK representative coming out to see you for a free measure and quote of your warehouse. From this you receive a PDF plan layout of your warehouse and can see how to best fit out the space. Unlike other companies who try to sell you what they have in stock, a MACRACK consultant will listen to you and understand your specific needs.

Our consultants know the MACRACK product inside & out and are willing to take the time and effort designing the perfect floor plan for you, maximising your warehouse design’s efficiency and capacity.

What to look for in your Warehouse

Want More Specific Info?

Custom Design

We also offer complimentary 3D CAD design of any custom parts you may need, this allows you to visually understand what you will be getting before you engage us. We are able to manufacture huge varieties of custom parts, because we actually are warehouse shelving manufacturers!

Other companies only import product, but we make everything here in our Brisbane office. The design team will work with you, from initial design, through to prototype and manufacture. 1 Off items, or 10,000 Off we have the capability to make anything.

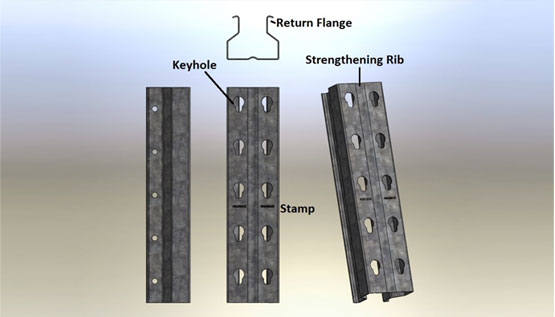

Key Features of the Macrack Design

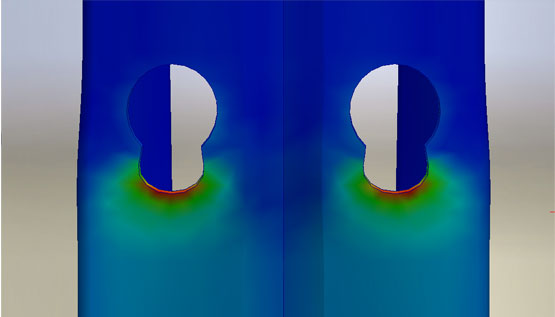

The secret to MACRACK’s superior warehouse racking systems is the ingenious ‘keyhole’ design. With this design the beams easily slots in and out of the frame because of the extra clearance. Other companies use different shapes which tend to ‘stick’ in the frame and can cause fatigue to the upright over time. With a round surface to distribute the weight of the beam, we ensure maximum distribution of the load throughout the frame.

The rounded bottom of the keyhole also allows for even distribution of weight into the uprights, reducing the directional force from the beam. This is the engineering excellence that sets us apart from the competition.

The Macrack Beam

Macrack use a roll formed section beam most of the time, which essentially is 2 sections of coil steel rolled into ‘C-sections’. The sections are then pressed together to create a solid structure which disperses the weight evenly through the beam and creates a sealed environment preventing contaminates and rust areas. Unlike a ‘Open Section’ beam where dust, particles, bugs and rust can hide, these beams are fully enclosed and don’t allow for this to happen.

Other companies have turned towards the I-beam design in their warehouse racking systems, (this is also known as ‘dog bone’ due to the roll formed section profile looking like a dog bone). These beams may take similar weight loads to the MACRACK section, however are prone to damage as they roll around the axis essentially twisting the beam. This is not safe and the weight load then shifts to a point load on an edge of the beam.

This happens because unlike a box section the centre of the I-beam is weak, because it is so close together, so if your pallet accidently grabs the beam it will twist horizontally. That’s why MACRACK sticks with their quality beams, that are proven time and time again. For a warehouse design solution you can rely on MACRACK.

Get A Free Design And Quote

Ensure Your Warehouse Storage Solution Has A Lifetime Guarantee Call Us Today

Our Clients

Providing Quality Racking At Great Prices For Over 30 Years

“Customer service is exceptional. The staff are very friendly and helpful when I had any questions and queries. They provided me with all the information I needed and some that I didn’t even know I needed. When I organized something with them, they did exactly what they said they would do and they were always polite and punctual. The price is very competitive and I would recommend Macrack to anyone needing Racking Solutions.”

Paul C – Google Review

“Macrack Australia have been a pleasure to deal with on both occasions we have now used them. From the advice and suggestions given to maximise our space and storage, through to the team at install, we have had a very good experience and would highly recommend Macrack for your warehouse and storage needs. A+ Thanks Gary and the team.”

Mick A – Google Review

“I would like to take this opportunity to thank the team at Macrack for the quality of work and product they supply. The staff are wonderful and it is great to see such professionalism thru-out this company.

Jeff is a real asset to the business and it is always a pleasure to deal with the ladies in admin (Jo).”

Willie M – Google Review

“We have tried other brands of rackings, but hands down the product from Macrack is by far the better choice. Rackings are designed to test the extreme elements and most importantly high standard of customer service. Highly recommended!”

Victor S – Google Review

“I highly recommend Macrack to any business looking to install pallet racking or stock shelving. From designer Leo through to the professional staff who replaced all the shelving in our warehouse and installed new pallet racking. The co-ordination was great and they fitted in with our tight schedule. Any query was answered promptly. Pricing was very competitive as well.”

Brian D – Google Review

Get A Free Design And Quote

Ensure Your Warehouse Storage Solution Has A Lifetime Guarantee Call Us Today

Come in and have a look, have a chat, have a coffee. Our entire product is on display.

View Our Product Range

Contact Us

Phone: 1800 048 821

Phone: 07 3343 9788

Email: [email protected]

Address: 40-42 Devlan St, Mansfield, Brisbane QLD 4122

Mail: PO Box 2227, Mansfield, Brisbane QLD 4122

Despatch: 22 Devlan Street, Mansfield, Brisbane QLD 4122.