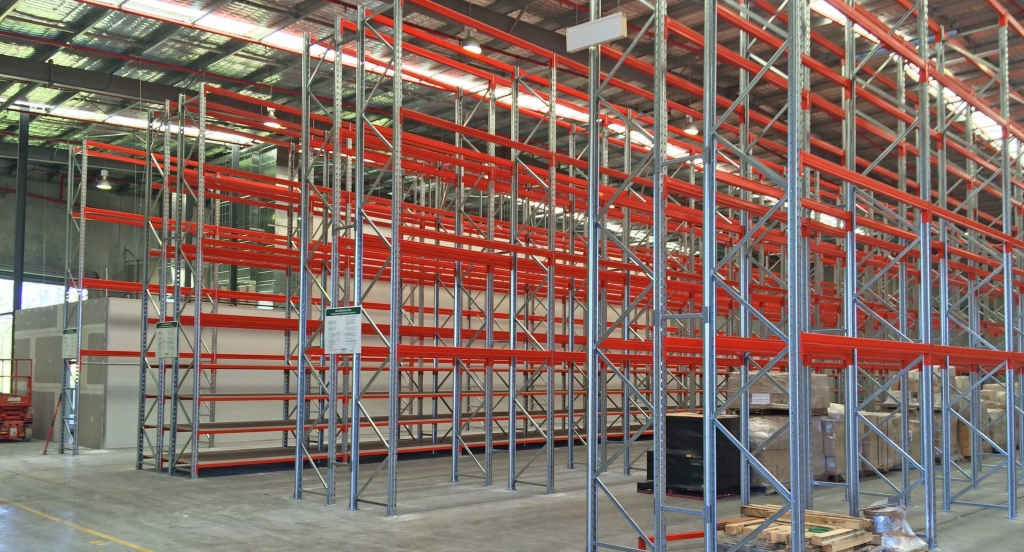

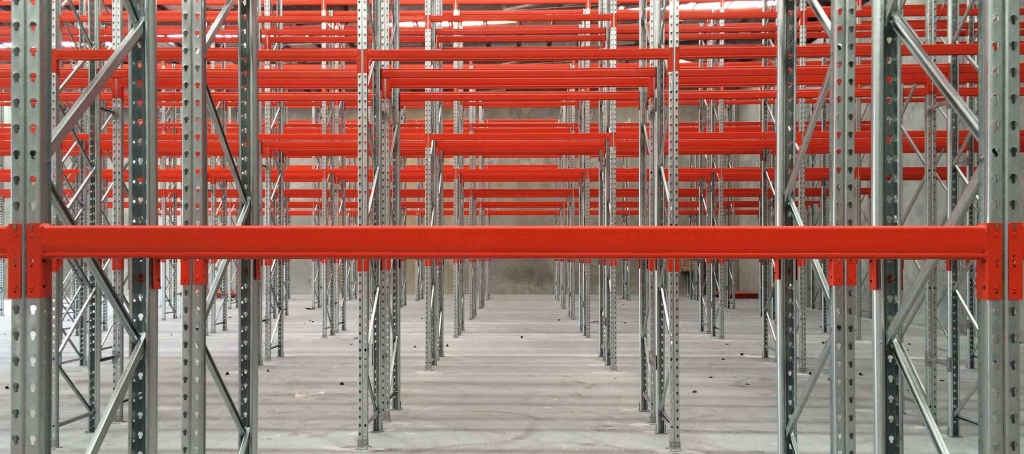

Pallet racking systems come in a range of different heights, depths, beam lengths, and weight capacities. In order to maximise warehouse storage and improve your warehouse processes, your pallet racking system should be designed specifically for your products and warehouse.

When calculating the ideal dimensions for your new pallet racking system you will need to determine the optimal frame height and depth, beam length, and weight capacity for your products, while taking into account the required clearance between racks and building components.

Frame Height & Depth

Most pallet racking standard sizes are derived from the imperial system using measurements of inches and feet. MACRACK pallet racking frames are designed in 3-inch increments with standard frame heights ranging from 3ft (914mm) to 29ft (8840mm).

Choosing the right height pallet racking for your product range and warehouse can increase storage capacity while saving floor space.

Our pallet racking frames can also be built with a customised frame depth that is suited to your pallets. Standard Australian pallet size is 1165 x 1165 x 150mm. For pallets of this size, a racking frame of 840mm deep is suitable frame depth. However, larger pallets, such as US (1219 x 1016) or European pallets (800 x 1200), or smaller Australian export pallets (1100 x 1100) will require custom sized rack frame depths.

Beam Length & Weight Capacity

Similar to our racking frames, our standard beams are built to accommodate standard pallet sizes measured in the imperial system of inches and feet.

The beam length in your pallet racking system should be based on how tightly packed your pallets will be as well as the size of the pallet and the amount of space available. You should also take into consideration whether or not your pallets have any overhang to allow for enough clearance between the load and the frame or between two loads stored on the same beam.

You will also need to take into consideration how many pallets will be stored on each beam. Longer beams can be used to store multiple pallets between each frame which will reduce costs, as it will reduce the number of frames needed. However, this is only suitable for lighter pallets, as less frames means a lower weight capacity. For the storage of heavier pallets, shorter beams are ideal as this will increase the number of frames needed and dramatically increase weight capacity.

Alternatively, if the size of your pallets and loads vary, a combination of different beam lengths can be used to create a pallet racking system tailored to your products with no wasted space.

MACRACK offer standard beam lengths from 4’6” (1372) to 13’ (3962mm). However, as no business or product range is the same, we can custom-make any length beam to suit your products and space at no extra cost. We can design racks with weight load capacities of 500kg per level, or 5000kg per level to best suit your needs.

Required Clearance Between Racks

When determining the dimensions of your pallet racking system you need to take into account the minimum clearances required between the racks and the building’s structures, as well as clearances around the pallet in the racking system.

It’s important to ensure that minimum clearances are observed between pallet racking and structural components of the building, such as columns, walls, beams, etc. This clearance is left to prevent the racks from coming into contact with the building’s components due to impacts (such as a forklift collision) or in the event of an earthquake. Without leaving the required clearance, contact between the rack and the building in the event of an impact could cause damage, and can even compromise load bearing capacity of both the rack and the building.

In accordance with the Australian Standards for Steel Storage Racking (AS 4084:2012), pallet racks need a minimum clearance of 200mm from building components such as walls and columns. Additionally, clearance from the top of the pallet to the underside of the load beam above should be a minimum of 75mm for beams under 6.0m, and 100mm for beams above 6.0m. There must also be at least 430mm clearance between back to back rows.

Quality Pallet Racking In Standard & Customised Sizes

Whether you’re looking for a stock standard pallet racking system to store standard Australian pallets in, or you need a more customised solution with tailored beam lengths and weight capacities, MACRACK has the perfect storage solution. With a locally based manufacturing facility in Brisbane, we can proudly offer customised storage solutions with short lead times across Australia. Plus, each of our racking systems come with a lifetime guarantee, so you can rest assured that they have been built to last.

Call Macrack today on 1800 048 821 for a free quote and warehouse design or fill out our contact form.