When calculating the storage capacity of your warehouse, the first thing to consider is the pallet size or the product size. This is the most critical part because it will influence the rest of the variables in the warehouse.

Measure Pallet Size

Take note of each of the following measurements for your pallet or product size:

- Weight

- Height

- Depth

- Width

These are the critical factors for anyone to know in order to supply you with proper layout/ design.

Note: Most standard pallets are 1165x1165mm in Australia.

Top Tip: Standard pallets fit onto a standard 840mm deep rack which is just enough for the pallet to sit on nicely.

Measure Warehouse Size

When it comes to choosing the right warehouse (or measuring up your current warehouse) there are a lot of factors to consider.

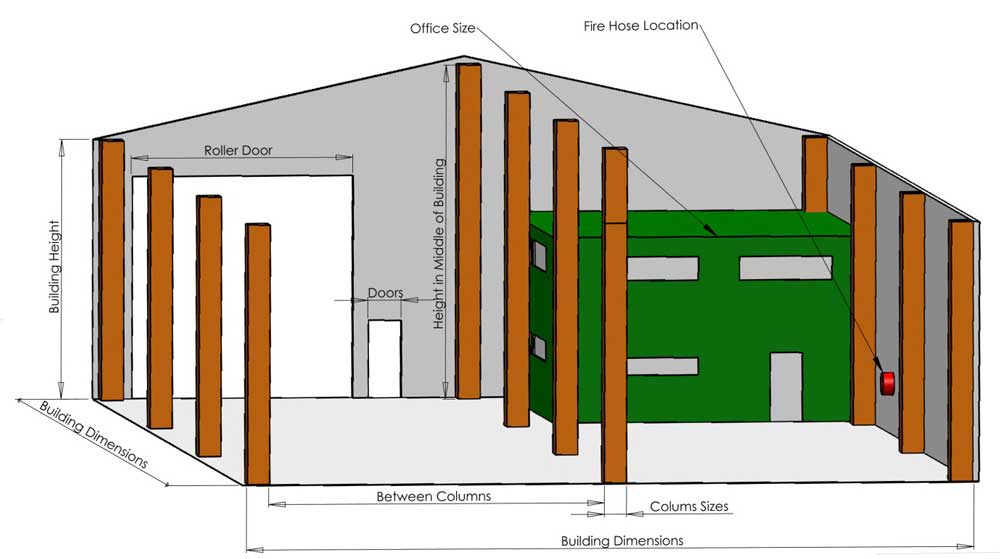

1) Measure Overall Building Size

First and foremost is the ‘overall building size’, this will give an approximate area to work within. Measure from wall to wall and include any:

- Offices,

- Toilet blocks,

- Corners,

- Stairs

- Etc.

Sketch this out on a piece of paper. This will give you a good overall starting warehouse layout which then can be refined. After doing this we can move onto the next step.

2) Measure All Other Components

Circumnavigate the warehouse and measure all other components of the warehouse such as:

- Building columns

- Fire doors

- Roller doors

- Electrical boxed

Measure all the components back to a wall to make sure you have a correct distance. Also, make sure you take note of building column sizes and door sizes.

Note: Try not to measure one point to the next, this gives a running measurement. Which means if one measurement is out, it will affect the rest.

3) Measure Building Height

Now you also have to measure the height of the building. Be sure to measure on the sides of the warehouse as well as the middle, since most roofs are pitched the measurements will be different and you may be able to store a little bit more depending.

Sketch this up on your plans and you have a great start to working out the best layout for you!

Top Tip: Since the majority of people do not have access to CAD (Computer Animated Design), a good tip is to sketch the warehouse on grid paper or adjust Microsoft excel to be a scale grid to work off.

A Typical Pallet Racking System:

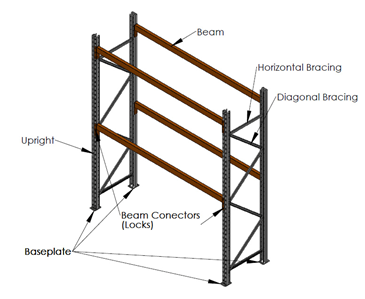

Pallet racking is made from two main components:

- Frames

These are the uprights posts and the bracing between. Frames are generally 840mm deep and can be at any height

- Beams

These are the cross members that lock into the frames. They can be adjusted to any height to suit your pallets

Note: Beams come in a couple standard sizes

- 1 pallet wide 1372mm,

- 2 pallets wide 2590mm,

- 3 pallets wide 3658mm.

Based on your warehouse measurement you can now start plotting how many bays you can fit into your warehouse. Don’t forget to include about 100mm for the frames. Additionally, racks need to be 200mm off from a wall (or column), and back to back racks need to be 430mm between racks according to the Australian standards.

When deciding how many pallets high your racks can take, use the height of the pallet and add another 100mm to the underside of the next beam, to make sure it’s clear. Each beam is about 100mm high, then you add the next pallet on, and so forth.

Make sure that you stop before the top pallet hits the ceiling height. This should give you the total number of pallets high you can go.

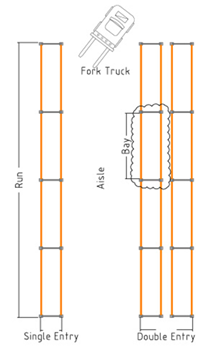

Consider Forklift Size

If you already have a forklift, you should be able to measure the turning circle (including the pallet in front). This should give you a good idea of what distances you need to be between racks. This distance can vary greatly depending on the type of forklift, so please double check.

Note: Normally for a ride on forklift, it would be about 4.5m, smaller electric forklifts may go down to 3m.

This will greatly affect the potential storage of your warehouse.

Free Warehouse Layout Plan Offer

MACRACK offers a free design service where we can meet you onsite to take measurements and create a plan layout for your warehouse. This takes all of the hard work out of calculating rack space and will allow you to visualise the pallet racking in your space.

If you’re looking for a quailty pallet racking solution call MACRACK on 1800 048 821 today and take advantage of our free warehouse design offer! With over 30 years of manufacturing experience, when it comes to warehouses and pallet racking, we’re the experts. Call us today for quality storage solutions at competitive prices.