Before you rush off to buy some pallet racking, have a think about your product and how your business operates. No two businesses are the same and there are vast differences between even how different branches in the same organisation operate.

Understanding your Storage needs

Here are a couple things to ask yourself before you begin;

- Is there fast and slow product?

- Need a staging area?

- How quickly does your product move?

- What will be the movement around the warehouse?

- What type of forklift do you have? What’s its turning circle?

- Which type of racking do you need? Will pallet racking suit?

- What is the ideal amount of storage?

- What size is your product?

- What are your restraints? Schedule? Downtime? Budget? Floor Space?

Talk about storage systems with key figures in your business.

If you are reading this, chances are that you are project managing the new warehouse fit out. You probably have experience, but like the scouts say, ‘be prepared’. There is nothing worse than thinking you know everything about a subject to soon realise you are in over your head.

Warehouse Staff: Talk to the people who actually use the racking on a day to day basis. see if they have any issues with the current warehouse layout… you may be surprised.

Directors: Have you got a budget from corporate? Are you going to use cap-ex? Do the directors have a plan for the future? Maybe 5 year plan or goal?

Choose the racking system that suits your product

Get all the dimensions and weights of your products before you go looking for racking. Often it’s the last thing you think of, but the most important. Not everyone has the same product, especially if you don’t exclusively use pallets to move products.

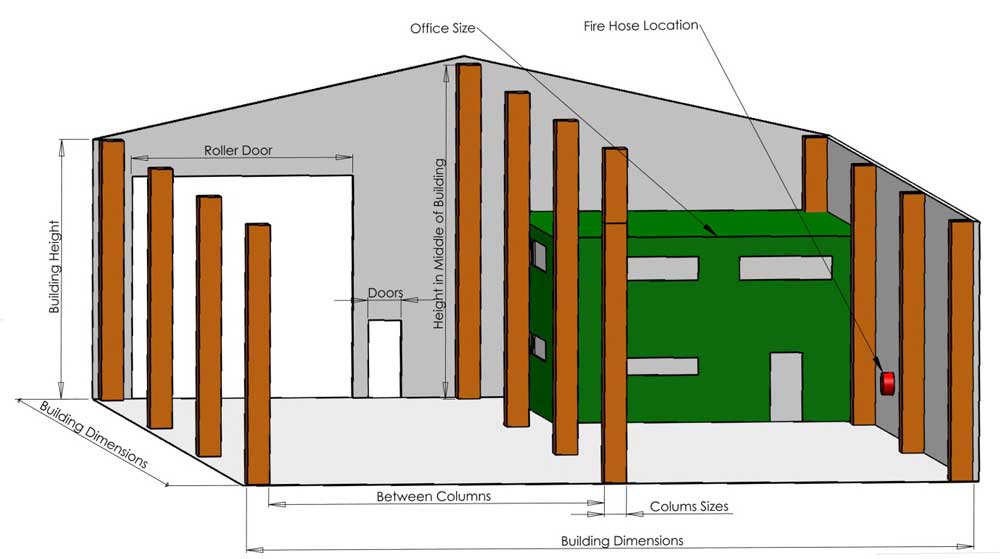

Measure your warehouse

To measure up your warehouse is quite simply and you can do it yourself. You might even want to put together a basic plan, which is great to visualise how everything is to be laid out. But don’t forget to look up and don’t forget the little bits and pieces. For example, if you have a fire hydrant, you want to be well away from that as a matter of safety and standards.

Do you want the racking to go outside? If so it’s prudent to get galvanised racking to ensure it lasts. Galvanised racking should never rust and when you are storing tons of weight on a rack, rust can be a real issue.

Assembly and Installation of Racking

Who is going to install your racking? Its strongly recommended that you get professionals to install your racking, if you don’t do so you are running the risk of incorrect installation that could end up disastrously.

Things to look out for include;

- Using genuine brands and not having a mixture.

- Plumb & level racking

- Dynabolting

- Safe Work Load signs

- Correct new footplates

- Make sure its square

- Applies to AS 4084: 2012

Second Hand Racking

2nd hand racking you more often than not get stung with product that doesn’t conform to the latest standards. Even worse, second hand racking may no longer be certifiable to the latest standards AS 4084-2023, which leaves you in a liable position. Secondly, you may not know what brand it is and it may not be compatible with your current system.

Call now for a chat! 1800 048 821