Food Grade Pallet Racking

Macrack has devised a new pallet racking solution for companies who face issues regarding food contamination, cleanliness, surface harbouring, and sanitation. Ask us about food grade pallet racking.

- Do you produce food?

- Do you need to store pallets in your clean area?

- Are you in an industry where contamination is an issue?

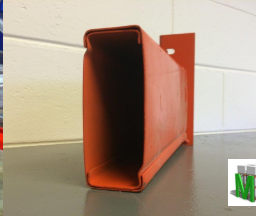

Introducing the “sealed compartment pallet racking system”:

- Clean Steel

- Made from either Hot Dip or Pregalvanised steel

- All compartments are sealed

- Can be used for

- Pallet racking

- Drive in racking

- Double deep store

- Industrial shelving

- Can be pressure and steam cleaned

- Takes the same weight load as regular pallet racking

- Bulks storage of goods in clean areas

- Reduced foodtrap areas

Pallet Storage in Food areas

Read this exert from ANZFA, regarding requirements for food prep areas;

AUSTRALIA NEW ZEALAND FOOD AUTHORITY SAFE FOOD AUSTRALIA STANDARD 3.2.3

Division 4

—

Fixtures, fittings and equipment

12 General requirements

(1)Fixtures, fittings and equipment must be:

(a) adequate for the production of safe and suitable food; and

(b) fit for their intended use.

(2) Fixtures and fittings must be designed, constructed, located and installed, and

equipment must be designed, constructed, located and, if necessary, installed, so that:

(a) there is no likelihood that they will cause food contamination;

(b) they are able to be easily and effectively cleaned;

(d) to the extent that is practicable, they do not provide harbourage for pests.

(3) The food contact surfaces of fixtures, fittings and equipment must be:

(a) able to be easily and effectively cleaned and, if necessary, sanitised if there is a likelihood that they will cause food contamination;

(b) unable to absorb grease, food particles and water if there is a likelihood that they will cause food contamination; and

(c) made of material that will not contaminate food.

Clean Pallet Racking:

Macrack always strives to improve its own design and reach the requirements of the industries that it supplies to. In doing so, we have developed a pallet racking system that allows for a reduction in food harbourage areas, sealing off catchment areas. Essentially ending what has been a bit of a sticking point (pardon the pun) for the food industry.

The main problem seen in the food industry is the potential for food scraps and other contaminants to build up in lips and crevasses. In turn this attracts insects and vermin, as well as creating general food contamination and spoilage.

- To counter this potential issue, Macrack has created a clean system of sealed bracing where the normal ‘C’ Channel is now completely sealed and unable to catch food scrap.

- All parts of the system are galvanised which in turn means that they can be chemically cleaned, pressure cleaned, or steam cleaned without the risk of rusting.

- There is no paint in the racking system which means no potential for paint flakes to peel off into the goods.

- Floor Channels for drive in racks are inverted to create a catchment free zone of particles and food scraps. This further allows for easy clean up and wipe downs if needed.

Certification

Macrack’s racking systems are certified to all the latest racking standards. This guarantees that you have the highest rated and safest racking available.

Lifetime warranty

You can also be confident in your decision to use Macrack with our life time warranty. Other company’s offer no warranty at all, so double check before you take the leap.

100% made in Australia

Macrack is 100% Australian made. Not many other companies can claim this, but it is a very important factor. If you buy from an importer, you can never be sure of the quality, nor do you know if they will be around to support you further down the road. Stick with Australian, support Australian manufacturing.