Macrack is Australia’s premier warehouse storage solutions provider. Our long term belief in manufacturing in Australia, with Australian steel, has made us a trusted name among some of the country’s leading brands. Our headquarters and manufacturing facility is based in Brisbane and we ship Australia wide with highly skilled installers in every state. Established in 1983 and with over 40 years in business, we stand behind our product with a lifetime guarantee.

It’s not just our product that sets Macrack apart. Our team has years of experience designing warehouse layouts across a wide range of industries. It’s this experience that allows our team to design solutions beyond just a racking system, helping our clients to solve warehouse inefficiencies and improve warehouse flow. Need Pallet Racking in Far North QLD? Contact the team at Macrack today for a free warehouse design and quote on 1800 048 821.

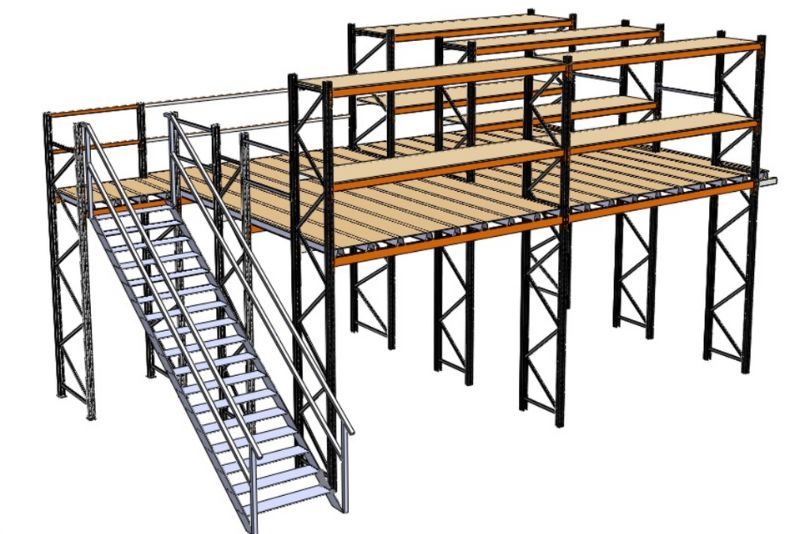

Not sure when to engage a racking company? You can contact us for advice before you have even signed a lease for a property. You may even reduce the size of the warehouse needed and save on your ongoing property costs with a raised storage area. A racking based raised storage area (sometimes referred to as a racking based warehouse mezzanine floor or multi-tier racking system) takes advantage of the air space in a property by building new levels supported by the racking structure. These new levels can be used as additional work floors or increased racking capacity, for stock picking and more.

Warehouse Storage Systems

As well as pallet racking, we also offer a wide range of other products for all your warehouse storage needs, established in 1983 we have 40 years of manufacturing experience and no challenge is too hard. Each system can be fully customised to suit your particular product, but they will always remain affordable. Check out our wide range to see what will suit your business and storage needs.

SELECTIVE RACKING

The cheapest and most common form of storing pallets.

Macrack offers a huge range of pallet racking options including heights, weights, widths, configurations. In stock and ready to go, if you need a lot or a little we can quickly supply you.

DOUBLE DEEP RACKING

Allows you to store pallets 2 deep, accessing them with a pantographic forklift.

If you want to maximise your warehouse space, have a look into deep store, where you could double your warehouse capacity in the same size area by having a second set of racks directly behind the first.

PUSH BACK RACKING

Last in first out (LIFO) system of storing pallets using mechanical carts that push back.

This storage system is perfect for storing multiple lines of pallets when that need to be readily accessible. Store 2-6 pallets deep, but always load and unload from the front of the rack, as each pallet pushes back and rolls forward when the front is taken out.

DRIVE-IN RACKING

The most space efficient way to store pallets.

Drive in allows you to store pallets in 3 dimensions; sideways, up & down, back & forth. Actually driving into the racking system you can access a huge amount of pallet without the need for aisles.

PALLET FLOW

First in first out (FIFO) Pallet racking. Where the pallet are fed in from the back and roll to the front on industrial tracks.

If you need to constantly turn over your product or need to increase your efficiency, Pallet flow might be the way to go. A true FIFO solution to pallet storage. Store up to 20 pallets deep and have them constantly turning over.

NARROW AISLE RACKING

Narrow Aisle or Furniture Racking is a system specifically for large cumbersome product.

Essentially a large scale pigeon hole rack allows a stock picker to move through the aisles as well as up and down rack accessing each bay. Storing bulky items, but having minimal aisle space.

INDUSTRIAL SHELVING

If you need extra shelving in your warehouse we have a huge variety to choose from.

Cheap economical solution for some heavy duty shelving systems, choose sizes, heights, weight capacities and what type of shelving. Timber shelves, Mesh shelves, Steel Shelves great way to get some more storage.

LONG SPAN SHELVING

Cheaply and efficiently store small parts in what is described as a scaled down version of pallet racking.

Standard shelving units that are about head height with 3-8 shelf levels per bay. Very cost effective way to increase hand picking storage. Simple to assemble yourself, and easily adjustable.

TYRE RACKING

Store all your car, truck and bike tyres in an orderly and efficient way.

Keep all your tyres neatly stacked away with a tyre rack. Have as many levels of tyres stored as you need, they sit firmly in the rack between two beams, which keeps them separated and efficiently stored.

CANTILEVER RACKING

Store long packs of timber, extrusions and pipe.

Cantilever racking system allows the storage of long items because the body is set behind the arms of the rack. It’s very flexible for storing odd shaped items and very particle, maximise your floor space with cantilever racking.

STEEL COIL RACKING

If you have steel in a coil, you can increase your storage capacity with Coil Racks.

Using the same design as pallet racking, Coil Racks are designed to take steel or aluminium coils. Any size, shape, or weight, its customised to suit your product.

CABLE RACKING

Storing cables drums of all shapes and sizes.

If you have electrical cable drums or any product that comes on a roll/spool, cable racking is perfect for you. Store your drums and at the same time be able to unwind them. All sizes and weights can be catered for.

CARPET RACKING

Like the name implies Carpet racks are perfect for storing Carpet and Vinyl.

Much like a large pigeon hole rack, carpet racks allow you to store rolls of carpet on a shelf. These can be easily accessed at any point and allow for high density storage capacity.

A-FRAME

Store extrusions or lengths of material upright, leaning on an industrial A-Frame.

If you need to store lengths of mouldings, extrusions, pipe or timber, try A-frame racking. This system allows you to access each single extrusion independently, and keeps them neat and separated. Perfect for hand picking, manufacturing industries.

SHEET RACKING

Sheet racking is a pallet racking derived system designed for the storage of sheet materials such as sheet metal, wood, and plastic. Sheet racking can be customised to fit a wide range of sheet materials of varying weights, lengths and widths

RACKING PROTECTION

Protect your racks from being damaged by forklifts and MHE.

We have a huge range of protective items to prevent forklifts and other mechanical equipment damaging the racks. Dependant on what you need we will have a solution.

RAISED STORAGE AREAS

Expand your floor space by putting in a warehouse mezzanine floor.

Design and engineered to suit you and your storage needs, tailor make it to work with your operations. 1 level, 2 levels, 3 levels anything is possible. Comes with stairs, pallet gates, built in shelving and hand rails.

FREE WAREHOUSE DESIGN

As experts in storage and shelving, we know a thing or two about warehouse efficiency. We provide a free warehouse design service and advise you on the best storage solutions to suit your unique business needs

Featured Products

First In First Out

In a First In First Out racking system the first pallet place in will be the first pallet out.

A simple FIFO racking system is selective racking and a more complex example is pallet flow racking.

Selective Pallet Racking Far North QLD

Selective pallet racking is what probably comes to mind when you think of pallet racking. It has the advantage of increased stock availability, which is great for areas that have or may require high product differentiation. A selective racking system is one pallet deep which makes any pallet readily available for selection. To reduce the footprint taken up by aisles in your warehouse, selective racking rows can be installed back to back. Selective racking can also be combined with industrial shelving which allows a racking row to have a combination of palletised products, boxes or individual items.

Last In First Out

In a Last In First Out racking system the first pallet placed in will be the last pallet out. A simple LIFO racking system is double deep racking and a more complex example is push back racking.

Push back racking

Push back racking is a high density Last In First Out (LIFO) racking system built with a track and cart on an incline. As a high-density system, push back racking can be configured two to six pallets deep. In this system, each new pallet added to the front of the track pushes the pallets behind further up the track. When a pallet is removed, gravity brings the remaining pallets behind forward.

Macrack Pallet Racking

With over 40 years of experience manufacturing and installing racking systems for Australian companies, we have total confidence in our warehouse racking systems and our lifetime guarantee. Whether you are looking for a new warehouse location or you want to stay and improve your warehouse layout and configuration, Macrack is the team to contact. As experts in storage and racking, we know more than a thing or two about warehouse efficiency. We provide an exceptional free warehouse design service and can advise on the best storage solutions to suit your unique business needs. Contact us today on 1800 048 821

Our wide range of products caters to many applications, from storing palletised products, cable spindles, furniture, industrial materials, carpet rolls and steel coils to other customised solutions. Our range includes:

Our Clients

Providing Quality Racking At Great Prices For Over 40 Years

“Customer service is exceptional. The staff are very friendly and helpful when I had any questions and queries. They provided me with all the information I needed and some that I didn’t even know I needed. When I organized something with them, they did exactly what they said they would do and they were always polite and punctual. The price is very competitive and I would recommend Macrack to anyone needing Racking Solutions.”

Paul C – Google Review

“Macrack Australia have been a pleasure to deal with on both occasions we have now used them. From the advice and suggestions given to maximise our space and storage, through to the team at install, we have had a very good experience and would highly recommend Macrack for your warehouse and storage needs. A+ Thanks Gary and the team.”

Mick A – Google Review

“I would like to take this opportunity to thank the team at Macrack for the quality of work and product they supply. The staff are wonderful and it is great to see such professionalism thru-out this company.

Jeff is a real asset to the business and it is always a pleasure to deal with the ladies in admin (Jo).”

Willie M – Google Review

“We have tried other brands of rackings, but hands down the product from Macrack is by far the better choice. Rackings are designed to test the extreme elements and most importantly high standard of customer service. Highly recommended!”